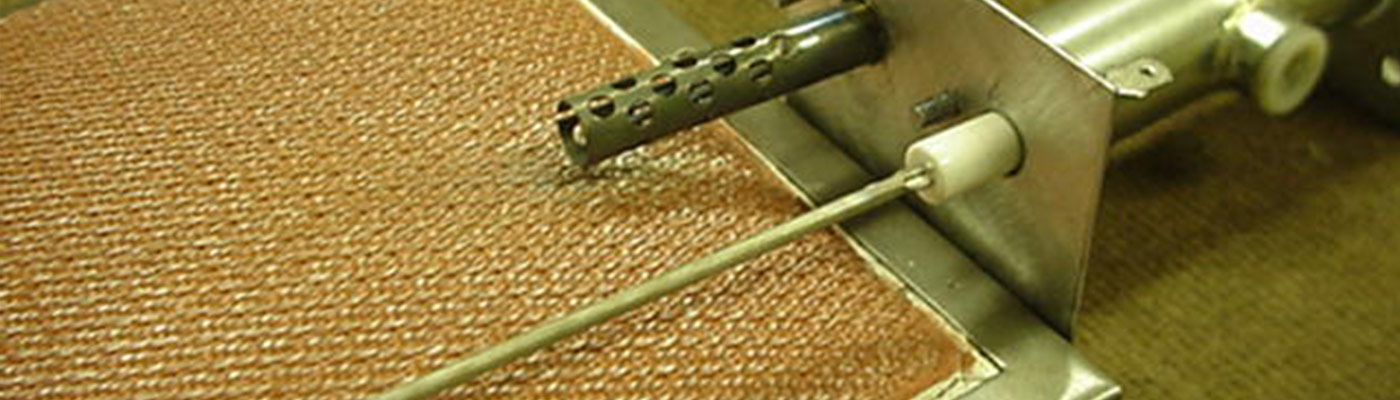

Woven Ceramic Fabric Burner

The woven ceramic fabric burner (WCF) is a flexible burner that can be used inside heat exchangers for a variety of applications. It features a less complicated design to get an even distribution of heat, thus not needing a full distributor nor baffle plates.

WCF Burner Specifications

The woven ceramic fabric burner (WCF) can maintain a continuous operating temperature of 1,100°C (max). This infrared burner can operate as both blue flame and infrared which allows you to have to have multiple inputs to better match the heat to your specific application. The typical loading of 450 BTU/Sq. inch in infrared and 4,500 BTU/Sq. in blue flame.

You can anticipate about a minute to get the warm temperature desired when using a WCF burner. You may need additional grounding screen from the average flame sense capability from this burner.

Woven Ceramic Fabric Burner Applications

The woven ceramic fabric burner (WCF) can be used in a variety of industries including commercial cooking, hot water production, industrial processing and breweries. Some of the typical applications the WCF burners are used in are boilers, steamers, fryers and pool heaters. Typically for WCF, we do cylindrical burners, but we can do other shapes as well.

Our woven ceramic fabric burners are manufactured custom for each application. Contact Solaronics to learn more!

- Continuous operating temperature of 1,100°C (Max)

- Typical loading of 450 BTU/Sq. inch in infrared

- Typical loading of 4,500 BTU/Sq. inch in blue flame

- Medium warm up period - usually takes less than a minute to get to temperature

- Very flexible - good for cylindrical burners

- Higher back pressure, thus not needing a full distributor/ baffle plate

- Good as infrared or blue flame

- Average flame sense capability- may need additional grounding screen