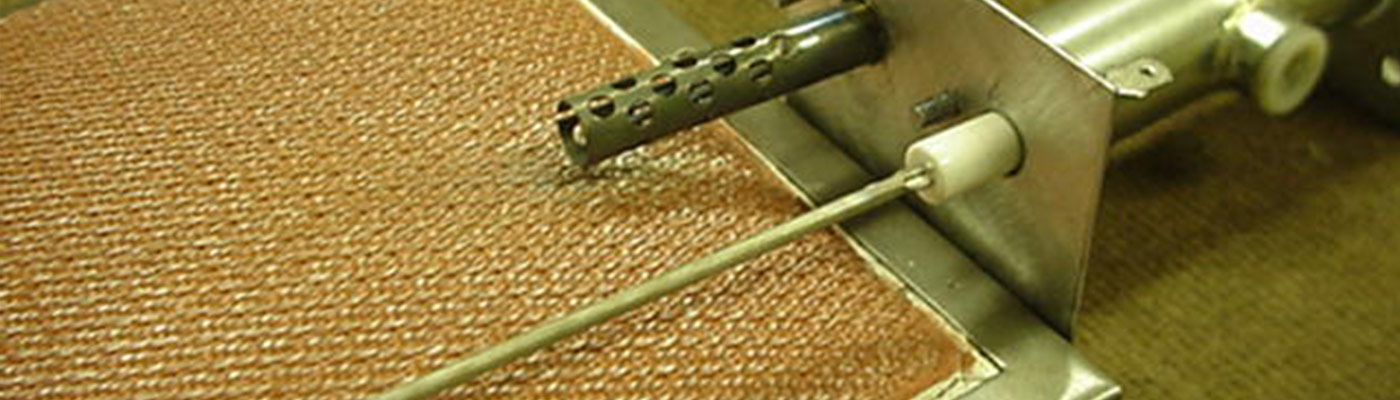

Wire Mesh Burners

Solaronics wire mesh gas burner is a cost-effective burner for a variety of applications. This burner often features a flat square or rectangle panel with lower flexibility. The wire mesh gas burner is very robust against shipping and impact damage. Gaskets are not used in the fabrication of the burner so there is no chance of contamination occurring.

Wire Mesh Burner Specifications

The wire mesh gas burner can maintain a continuous operating temperature of 1,300°C (max) and typical loading of 200 - 400 BTU/Sq. inch in infrared. The smaller depth of the wire mesh makes the heater more susceptible to backlight or backflash. Since the burner is completely metal, it is more conductive than a tile burner and provides a strong flame sense capability. This reduces nuisance shut-offs and service calls due to a weak signal.

Our wire mesh gas burner can be manufactured in different materials depending on your application. These materials include Inconel, Incoloy, Kanthal, various stainless steel, and much more. You can anticipate a medium warm-up period of less than a minute to get the full temperature to output infrared (IR), and it will oxidize over a period of time depending on the environment.

Wire Mesh Burner Applications

The wire mesh gas burner can be used in a variety of industries including commercial and residential cooking. Some of the typical applications of these burners are used in our broilers in ovens, open vat fryers, and rotisserie burners in grills.

Solaronics wire mesh gas burners are manufactured custom for each application. Contact us to learn more!

- Continuous operating temperature of 1,300°C (Max)

- Typical loading of 200 - 400 BTU/Sq inch

- High impact resistance

- Low flexibility (not suited for exotic burner designs)

- Medium warm up period - usually takes less than a minute to get to temperature

- Low backpressure - distributor is usually needed, depending on the weave and layers utilized

- Not well suited for blue flame

- More prone to back flashing

- Expansion can be an issue if not properly addressed

- Excellent flame sense capability

- Extremely low risk of contamination - burner does not have fibers or gaskets that could come loose

- Limited on size - burner has a risk of back-flashing if surface area is too large

- Will oxidize over a period of time