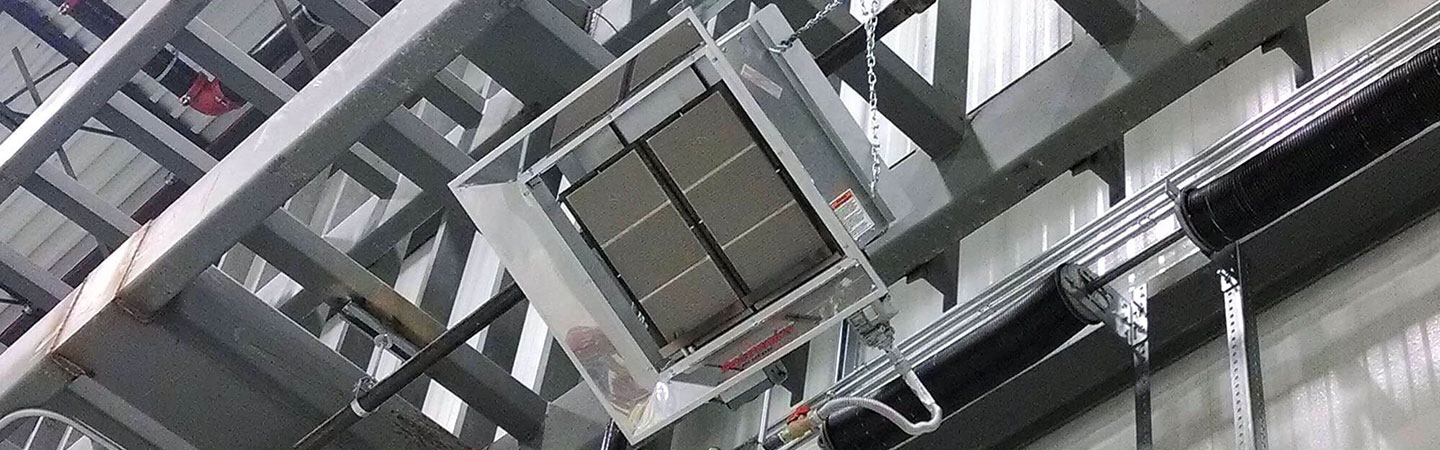

Infrared Heat Exchanger

The flame produced by the burner heats the combustion chamber and heat exchanger(s) and causes them to reach temperatures in the range of 200° to 1000° F. Infrared generated is in the range of 300 to 6500 BTUH/ft2, and thus the term ‘low intensity’.

The combustion chamber is made of 16 gauge heat-treated titanium coated aluminized steel. The heat exchangers are made of 16 gauge black steel, heat-treated aluminized steel, or 304L stainless steel. Each provide 1.052 per square feet of radiant surface per linear foot. The last heat exchanger in each system incorporates a spiral turbulator for increased efficiencies.

The 10’ and 5′ sections are joined by either a swaged-end style or standard compression coupling tube clamps. These clamps are made of two layers of 18 gauge (0.052″) aluminized steel or stainless steel. The inner sleeve has precision meshing teeth for even draw and pressure. Each tube clamp is closed with four 5/8″ zinc plated carriage bolts to 65 ft. lbs. torque. A #5 malleable iron turnbuckle-5/8″ eye to eye is also available as an accessory.