Ceramic Plaque Burners

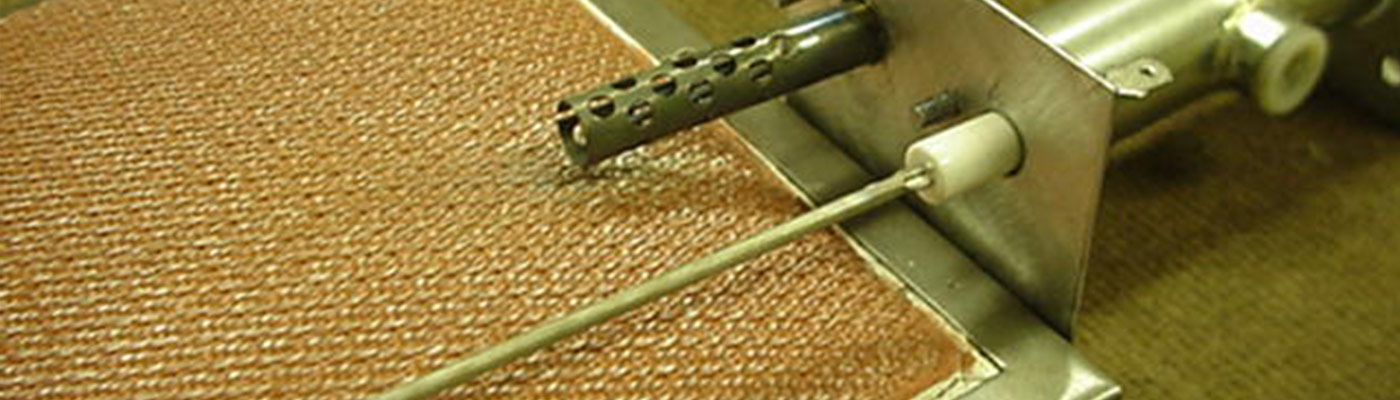

With over 50 years of historical field data, Solaronics ceramic plaque gas burner has proven its reliability for a variety of applications. The gas burner ceramic plaque is ideal for infrared surface combustion. This inexpensive gas burner features a flat square or rectangular ceramic tile that is typically ½” thick and is a great insulator for relevant applications.

Benefits of Ceramic Plaque Burners

- Cost-efficient

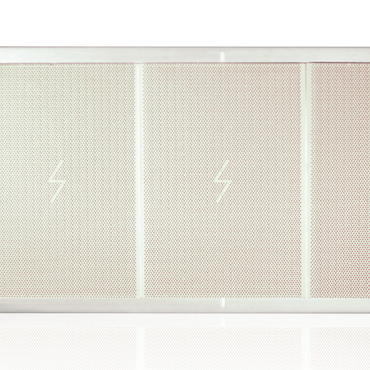

- A variety of surface patterns allow for maximum heat absorption

- Very durable

- Low thermal conductivity

- Infrared surface combustion

- Many types of applications

- Gasket material for sealing purposes

Ceramic Plaque Burner Specifications

The ceramic plaque gas burners can maintain a continuous operating temperature of 1,350°C (max) and typical loading of 300 BTU/Sq. inch in infrared. The ceramic tile has a depth of ½” which makes it less susceptible to backlight or backflash.

Solaronics’ ceramic plaque gas burners can block certain areas of the tile to manipulate the heat pattern that allows for even heat distribution. You can anticipate a slower warm-up period of up to several minutes to get the full temperature to output infrared (IR) and it will not oxidize. We use gasket material around the ceramic plaques and under the retainers for sealing purposes.

Ceramic Plaque Burner Applications

The ceramic plaque gas burner can be used in a variety of industries including commercial and residential food cooking and industrial process heating. Some of the typical applications of ceramic plaque gas burners include the use of fryers, broiler burners, BBQ burners, rotisseries, cheese melters, salamanders, and much more.

Our gas burner ceramic plaques are manufactured custom for your specific application. Contact Solaronics to learn more!

- Continuous operating temperature of 1,350°C (Max)

- Typical loading of 300 BTU/Sq. inch

- Ideal for infrared surface combustion

- Proven reliability with over 50 years of historical field data

- Best used as IR High insulation properties

- Inexpensive

- Not well suited for blue flame

- Low impact resistance

- Rigid, not easily shapeable

- Requires a mechanical means to affix it to a burner

- Tile face has a depth that makes it less susceptible to backlight or backflash

- Average flame sense capability

- Ability to block certain areas of the tile to manipulate the heat pattern

- Slower warm-up period - may take several minutes to get to full temperature to output IR

- Will not oxidize