Advanced Infrared Heating Technology

Solaronics high and low intensity infrared tube heaters and ceramic heaters convert a high rate of their input to infrared output. Input energy not converted into infrared is released as convected heat. Depending on the application requirements, our gas infrared heaters can be installed using direct or indirect venting. Unlike unit heaters, that allow heat to rapidly rise to the ceiling, Solaronics tube heaters direct their infrared heat towards the floor, where heat is invariably desired.

The difference between high intensity heaters and low intensity heaters is based on the operation. For example, a high intensity heater’s energy is emitted at a higher amplitude and temperature than a low intensity heater. High intensity heaters are also ventless. Low intensity infrared heaters operate at a lower temperature and may be installed with or without vent depending on the application. Both high and low infrared heaters work well in commercial and industrial applications. Low-intensity heaters may be used in residential garages. Contact us to learn more about which gas infrared heater is better suited for your application.

Solaronics' gas infrared heater lineup offers more than six decades of engineering experience and customer feedback to deliver the most efficient infrared tube heaters in the industry. With the customer service provided by our staff, while working side-by-side with our dedicated distribution network throughout the country, Solaronics offers a truly unique opportunity that sets us apart from our competition. Our design-build services offered for your application are also simply unmatched.

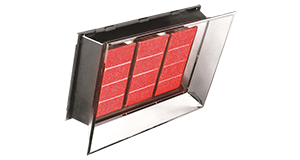

High Intensity Infrared Ceramic Heaters

For performance, reliability, and value, Solaronics high-intensity ceramic heaters provide energy-efficient heating solutions.

Learn More

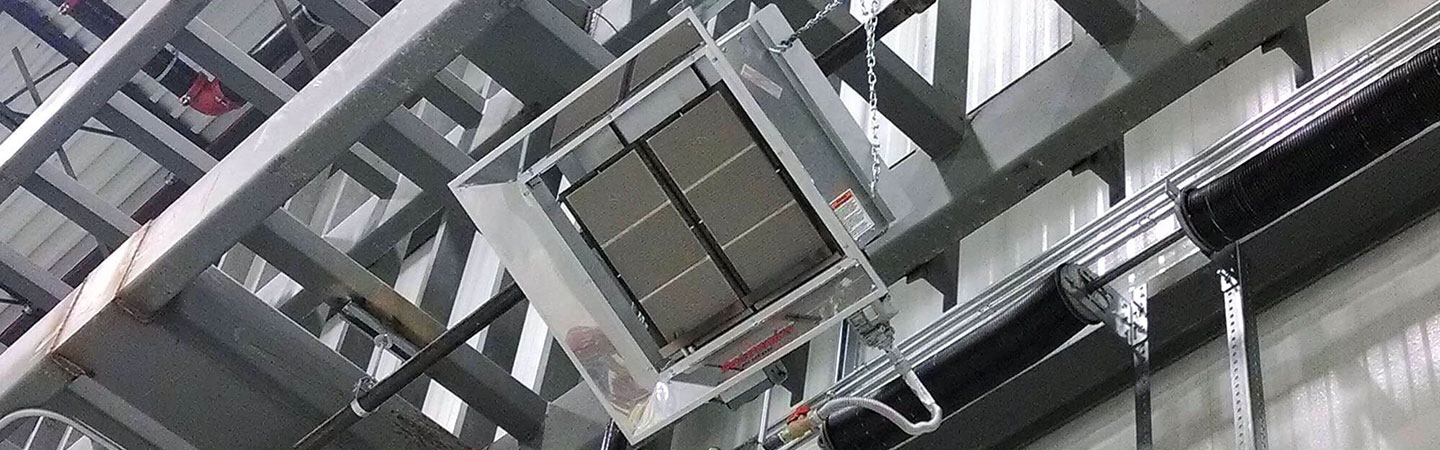

Low Intensity Infrared Tube Heaters

Solaronics Suntube low-intensity heaters are powered by a positive pressure burner which fires by 5′ or 10′ long steel tubes.

Learn More

Residential Infrared Tube Heater

Solaronics low intensity heater certified for use in residential garage applications.

Learn More

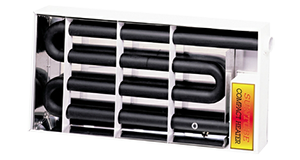

Compact Infrared Tube Heater (Discontinued)

Low intensity tube heater utilizing positive-pressure operation for any weather condition.

Learn More

Overhead DoorJet Door Heater

Fully stainless steel construction offering a watertight control cabinet for long-lasting and reliable operation.

Learn More